We understand your struggle. You run a warehouse or industrial facility and the lights are dim, flickering, and expensive. Employees, vendors, and customers complain about poor light quality. Your energy bills are piling up and your lights just aren’t working the way you want them to.

If you are dealing with these issues at your commercial facility, it all means just one thing… it’s time for a lighting upgrade.

But how do you pull that off while still actually running an industrial facility? Work crews running around the warehouse aren’t helping you operate more efficiently, distribute more products, or produce more material. In fact, they’re probably getting in the way.

Does it feel like your business environment is simply too complicated for a lighting project or retrofit? We are here to tell you it is not!

We encounter this problem all the time. From busy retail stores to chaotic warehouse floors, FSG has seen it all. We understand the need you have for better lighting, but we also understand your need to keep business rolling along.

Source: iStock

Getting Started with an Industrial Lighting Project

Shutting down for a few days or weeks simply isn’t a realistic option. That’s why you should find a commercial electrical contractor that approaches every lighting project the right way: your way.

There are several key points to consider when planning your project:

- Consider the size of your facility and where any machines, racking, or other equipment are located.

- The type of industrial facility you are operating makes a difference. A manufacturing facility will likely require more logistical planning than a storage warehouse.

- What methods can we use to complete the project while minimizing or eliminating operational interruptions? Accessing the facility after hours, or focusing on areas not in use during normal operating hours will keep your facility running efficiently while the work gets done.

That last item is the key: customizing the schedule so it makes the most sense for you. Not only does the project need to be completed on your timetable, but it also needs to be done in the most seamless way possible. (For busy customers, we strive for invisibility.)

If your employees, vendors, and customers can enter a better-lit environment without ever realizing an installation was underway, you can consider the job done correctly, the FSG way.

LED Lighting to Light the Way

If you have not upgraded your industrial lighting to LED, you are doing your facility a disservice. But you knew that already, right?

LED lighting is the ideal choice for lighting an industrial facility. By consuming less energy and providing a longer lifespan, LED lights allow you to lower energy bills and maintenance costs. Other less obvious benefits include reduced downtime at your facility while working on or replacing burnt-out light fixtures.

Perhaps an even greater benefit of LED lighting is improved safety. LED lighting produces less heat than traditional high-intensity discharge (HID) lighting, resulting in a cooler and safer work environment.

In addition, the improved light output and color rendering of LED lights improve visibility and reduce eye strain for workers. This leads to improved productivity and occupational health at your industrial facility.

Lastly, there are many incentives and rebates available for businesses that have not yet upgraded their industrial lighting to LED. If your company has a focus on ESG, a lighting retrofit is a great start.

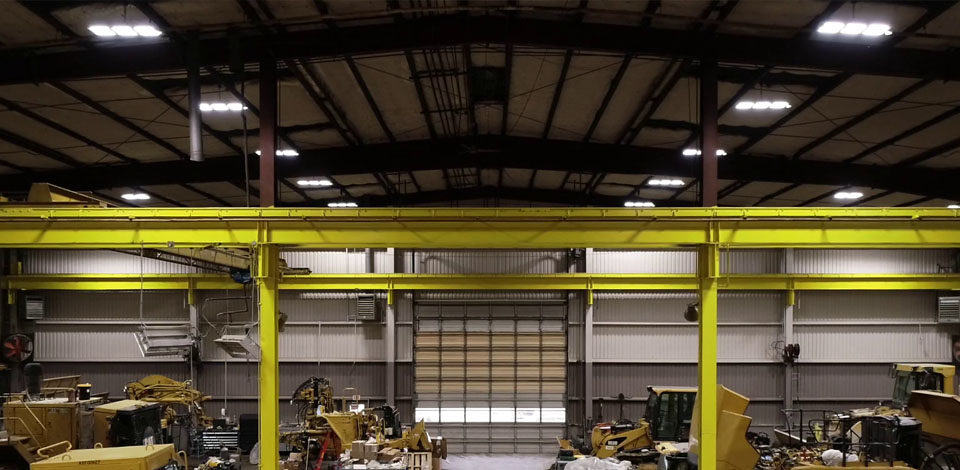

Source: FSG Media

The Customer-Centric Approach

At FSG, we take scheduling customization seriously. The last thing we want to do on a project is cause a disruption to your normal business operations.

We focus on the needs of the customer, and their unique facility operations and challenges when planning a lighting retrofit project.

FSG has worked in hundreds of warehouse, industrial, and manufacturing facilities across the country for over 40 years. We have seen and met every site-specific challenge imaginable.

View some of our project case studies

One example we are proud of is our work with Holt Cat, a Caterpillar dealer, and servicer in Texas.

Holt Cat’s campuses are huge, with multiple buildings and hundreds of light fixtures. The work environment is as hectic and fast-paced as the campus is big. Heavy machinery is constantly on the move from one area to another, and technicians swarm throughout the facility, fixing, upgrading, and servicing massive machines.

Our project management team knew that calling this operation to a halt was simply out of the question. Nor would it be possible to shut down one building at a time while FSG crews worked inside. Each building was part of a larger system for Holt Cat, and so closing one would mean causing the entire system to come to a stop. Instead, we had to get creative.

“I love doing the projects that have logistical challenges. From the design team to the sales team to the project management team, along with the customer, everyone has to come together and figure out solutions to the different obstacles you come across.”

Scott Dorsa

“It’s surprising to say, but a lot of companies are not as flexible as FSG when it comes to customizing a work plan to accommodate the customer. On this project, we mainly worked after hours”

Project Manager, FSG

By scheduling the installation for outside business hours–including nights and weekends–Scott and the FSG team pulled off an industrial lighting retrofit across Holt’s entire Irving, Texas, campus in less than one month.

You can watch our video about the project below:

Good lighting is an important part of your business. Getting high-quality, energy-efficient LED lighting installed without bringing the whole show to a stop is the only way to do it properly. That’s the only way FSG knows how to do it.

There’s No Time Like the Present

If you are ready to finally upgrade your industrial lighting, we are here now with offices across the nation ready to audit, spec, install, and maintain your lighting system.

Give us a call at (877) 293-6689 to speak with a lighting expert and learn about how FSG can help your industrial facility upgrade lighting without downgrading productivity.

If you are looking to purchase lighting products, install electric vehicle charging stations, or you need to fix that constantly burnt-out sign, we can help with those facility challenges as well.

Visit our website and contact us today!

Interested in joining the team? FSG is hiring! View openings and apply at fsgcareers.com.